About Us

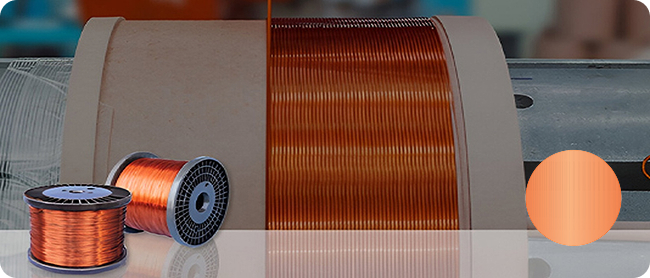

Walton Cables is the house of innovation and masterminding. It is a brand of Walton Hi-Tech Industries PLC, the leading electrical & electronic product manufacturer of Southeast Asia. This enormous manufacturing facility is located just beside the capital city Dhaka at Chandra, Gazipur, where the cable production facility spreads over 300,000 square feet. Walton Cables is a combination of cutting-edge technologies with state-of-the-art machinery.

We have the industry’s foremost integrated Cables R&I department to fabricate tailor-made products in accordance with the actual demand of consumers. Besides, we are the only manufacturer in the industry with fully equipped Chemical and Metallurgical laboratories. We strictly maintain our standard of sourcing all metals from LME-registered brands and other raw materials from globally acclaimed manufacturers. This combination of advanced machining, testing facilities, and premium raw materials ensures top-notch product quality and reliability.

Walton Cables possesses a strong manufacturing backbone with a metal processing capacity of 3,000 MT per year, insulation material producing capacity of 4,500 MT per year, super enamel wire producing capacity of 400 MT per year, and finished goods producing capacity of 420 thousand km per year.

The fundamentality of our business is to ensure the availability of diversified product lines with easy accessibility to the mass market. With our high production capacity and a very strong sales and distribution network, we significantly minimize risk for our clients by ensuring timely delivery of the best quality products with a highly committed approach. Walton Cables always endeavors to fully satisfy its customers by providing high-quality products, efficient delivery, and prompt customer service.

Cable categories

Walton

Cable you can trust on

100% Conductivity

100% Conductivity: High conductivity means low electrical resistance, so power flows with minimal energy loss, reduced heating, and improved power saving. This enhances efficiency, voltage stability, and safety in long-term operation

Best Quality

By effectively applying the 4M approach, we ensure skilled manpower, advanced machinery, quality raw materials, and standardized processes to produce high-quality products with Best quality assurance.

Anti-rodent & Anti-termite

Anti-rodent & Anti- termide: The special insulation prevents rodents and termites from attacking the cable, protecting against gnawing, wire cutting, and short circuits for long-term safety and reliability. Its eco-friendly repellent effect keeps pests away through odor without harming them, making it safe for the environment

UV Protected

UV-resistant insulation prevents cracking, hardening, and loss of dielectric strength when exposed to sunlight, making the cable suitable for outdoor and long-term use.

100% FR

Minimum 29.1% Limited Oxygen Index ensures excellent fire-retardant performance. The fire-retardant insulation resists ignition and significantly slows flame spread, reducing fire risk during short circuits or overloads and providing valuable time for evacuation and protection of property.

LME Copper

World-class LME-grade copper ensures superior quality and reliability. With excellent electrical conductivity, high tensile strength, and outstanding corrosion resistance, it provides the most durable and efficient conductor for safe and long-term power transmission.

Long Lasting

Long service life means the insulation and conductor resist aging, heat, moisture, and mechanical stress, reducing maintenance and replacement costs.

Fire Survival

FR materials are designed to self-extinguish when the flame source is removed, reducing fire spread, smoke, and toxic gases. They can withstand temperatures up to 950 °C for at least three hours without burning.

Highly Reliable

Reliability ensures stable performance under voltage, temperature, and load variations, minimizing faults, breakdowns, and power interruptions.

Oxygen Free

Oxygen-free copper has very low oxide content, which improves conductivity, reduces brittleness, and increases resistance to corrosion and long-term degradation.

Pb

Lead-free insulation is environmentally safe and non-toxic, complying with health and safety regulations and reducing hazardous exposure.

Utility Grade

Utility-grade cables meet national and international electrical standards, ensuring safe current-carrying capacity, insulation strength, and fault tolerance.

Certifications and Accreditations

BUET

Bangladesh University of Engineering and Technology

BUET Tested Walton cable samples and confirmed satisfactory voltage rating, electrical performance, insulation strength, current-carrying capacity, and flame-retardant properties, meeting all required standards.

PWD

Public Works Department

Walton Brand Cables are approved and enlisted in the PWD Schedule of Rates 2022 for Electro-Mechanical Works, confirming their suitability, quality, and compliance for use in government electrical projects.

ISO

International Organization for Standardization

ISO-certified Walton cables are manufactured under internationally recognized quality management systems, ensuring consistent production, superior quality, and reliable performance in every product.

MES

MES Cable Enlistment

MES approved Walton cables meet the strict quality and safety requirements for military and government projects, ensuring high reliability, durability, and dependable performance in critical installations.

CNAS

China National Accreditation Service

CNAS-accredited testing confirms that Walton cables are evaluated and calibrated by internationally recognized laboratories, ensuring accurate results and globally accepted quality, safety, and performance standards.

Utility Grade

Utility Regulatory Authority

Approval from the Utility Regulatory Authority confirms that the power cables are suitable for electrical installations in the Maldives, meeting required safety, quality, and performance standards for reliable utility use.

BREB

Bangladesh Rural Electrification Board

Walton cables are approved by BREB for open market sale, and the tested samples meet the standards followed by the Bangladesh Rural Electrification Board

CPRI

Central Power Research Institute

CPRI tested Walton cables meet international standards for performance, insulation, and durability, with flame tests showing no charring, dripping, shrinkage, erratic burning, or afterglow.

RoHS

Restriction of Hazardous Substances

TÜV SÜD Provided comprehensive RoHS compliance testing and certification, ensuring that hazardous substances in the products do not exceed strict international limits and are safe for health and the environment.

TICW

shanghai national center

Shanghai National Center tested and inspected electrical cables and wires, and officially approved, confirming compliance with required quality, safety, and performance standards.

BSTI

Bangladesh Standards and Testing Institution

BSTI-approved Walton cables meet national safety, quality, and performance standards, ensuring reliable operation, high durability, and compliance with all regulatory requirements for safe electrical installations

IAF

International Accreditation Forum

IAF-recognized certification confirms that the certifying body is internationally accepted and credible, ensuring that Walton cables meet globally trusted quality, safety, and performance standards.

DUET

Dhaka University of Engineering and Technology

DUET tested and evaluated, with satisfactory results confirming the cable’s electrical safety, performance, and reliability.

Some of Our Clients

Cables in Bangladesh

When you roam around the streets in Bangladesh and look up, you will know how much importance cables in Bangladesh have. The streets are filled with cables connecting a lot of houses with electricity and other connections. As the country moves towards a more digitalized nation, importance of such electrical things like cables and wire will be needed in huge quantity.

Walton is manufacturing cables that are of highest quality to ensure the best connectivity. You can check out our website for the electric cable price or visit our showroom as well.

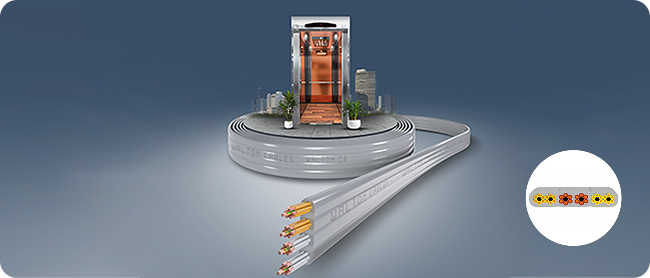

A cable used for the transmission and distribution of electrical energy is called electrical power cable. Power cable consists two or more electrical conductors join with an over sheath. It is used for the transmission of extra high voltages in a place where overhead lines are impracticable to use like, the sea, airfield crossing, etc. But underground cable is more costly as compared to aerial cable for the same voltage which is one of the main draws back of electrical power cable.

Construction of Cable

The power cable mainly consists of three main components, namely, conductor, dielectric, and sheath. The conductor in the cable provides the conducting path for the current. The insulation or dielectric withstands the service voltage and isolates the conductor with other objects. The sheath does not allow the moistures to enter and protects the cables from all external influences like chemical or electrochemical attack, fire, etc. The main components of electrical power cables are explained below in details.

Conductor

Coppers and aluminum wires are used as a conductor material in cables because of their high electrical conductivity. Solid or number of bare wires made of either copper or aluminum are used to make a power cable.

Insulation

The most commonly used dielectric in power cables is impregnated paper, butyl rubber, polyvinyl chloride cable, polyethylene, cross-linked polyethylene. Paper insulated cables are mostly preferred because their current carrying capacity is high, generally reliable and having a long life.

Inner Sheath

It is used for protecting the cable from moistures which would affect the insulation. Cable sheath is made up of lead alloy, and these strengths withstand the internal pressures of the pressurized cables. The material used for inner sheath should be nonmagnetic material.

Protective Covering

Lead sheath cables when directly laid down on the ground are damaged by corrosion and electrolyte. For protecting the cables against corrosion layers of fibrous material like paper, hessian, etc., or polyvinyl chloride is used. Layers of fibrous material spread with the waterproof compound to the outside of the electrical cable are called serving.

Over Sheath

It gives the mechanical strength to the cables. It protects the cable from overall damage like moisture, corrosion, dirt, dust, etc. The thermosetting or thermoplastic material is used for making over the sheath.