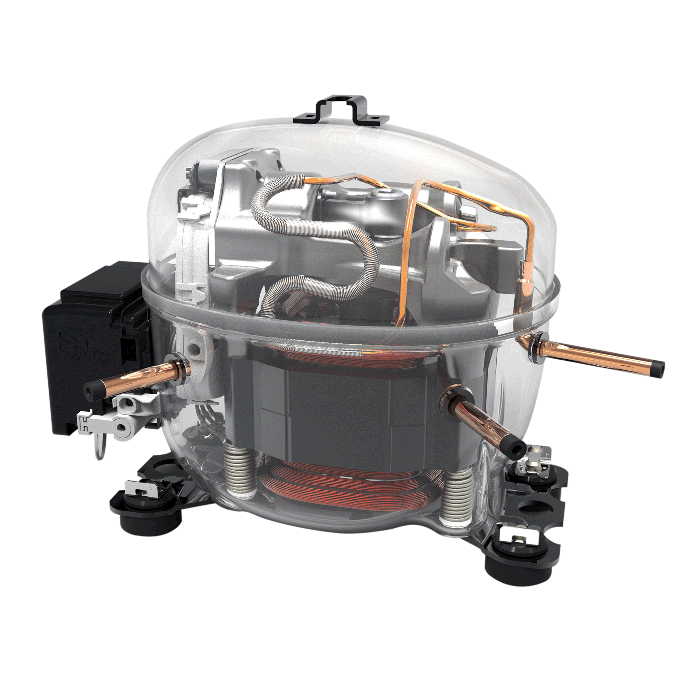

GVM44AA - Optimized efficiency.

- Refrigerant Type: R134a - Cooling Capacity: 122W. For quotation please contact : "' [email protected] '" |

(including bulk procurement or customized solutions), please reach out to

Walton Corporate Sales & Development

[email protected]

|

|

| General Features | |

| Type | Hermetic reciprocating compressor |

| Refrigerant | R134a |

| Nominal voltage and frequency | 220 / 50 [ V / Hz ] |

| Application type | Low Back Pressure (LBP) |

| Condensing temperature | 55 [°C] |

| Evaporating temperature | -23.3 [°C] |

| Ambient temperature | 32 [°C] |

| Maximum winding temperature | 130 [°C] |

| Expansion device | Capillary tube |

| Compressor cooling | Static |

| Normal Performance | |

| Test standard | ASHRAE/ ISO/ IEC |

| Noise dB (A) | 35 |

| Cooling Capacity (W) | With Capacitor: N/A Without Capacitor: 122 |

| Power consumption (W) | With Capacitor: N/A Without Capacitor:106 |

| COP (W/W) | With Capacitor: N/A Without Capacitor: 1.15 |

| Rated Current (A) | With Capacitor: N/A Without Capacitor: 0.69 |

| Mechanical Data | |

| Displacement volume | 4.38 [cm³] |

| Net weight | 7.5 [kg] |

| Oil type | Ester |

| Oil charge | 163[cc] |

| Oil viscosity | 15 [cSt] |

| Suction muffler | Semi Direct |

| Length, L | 184.5 [mm] |

| Width, W | 150 [mm] |

| Height, H | 169.5 [mm] |

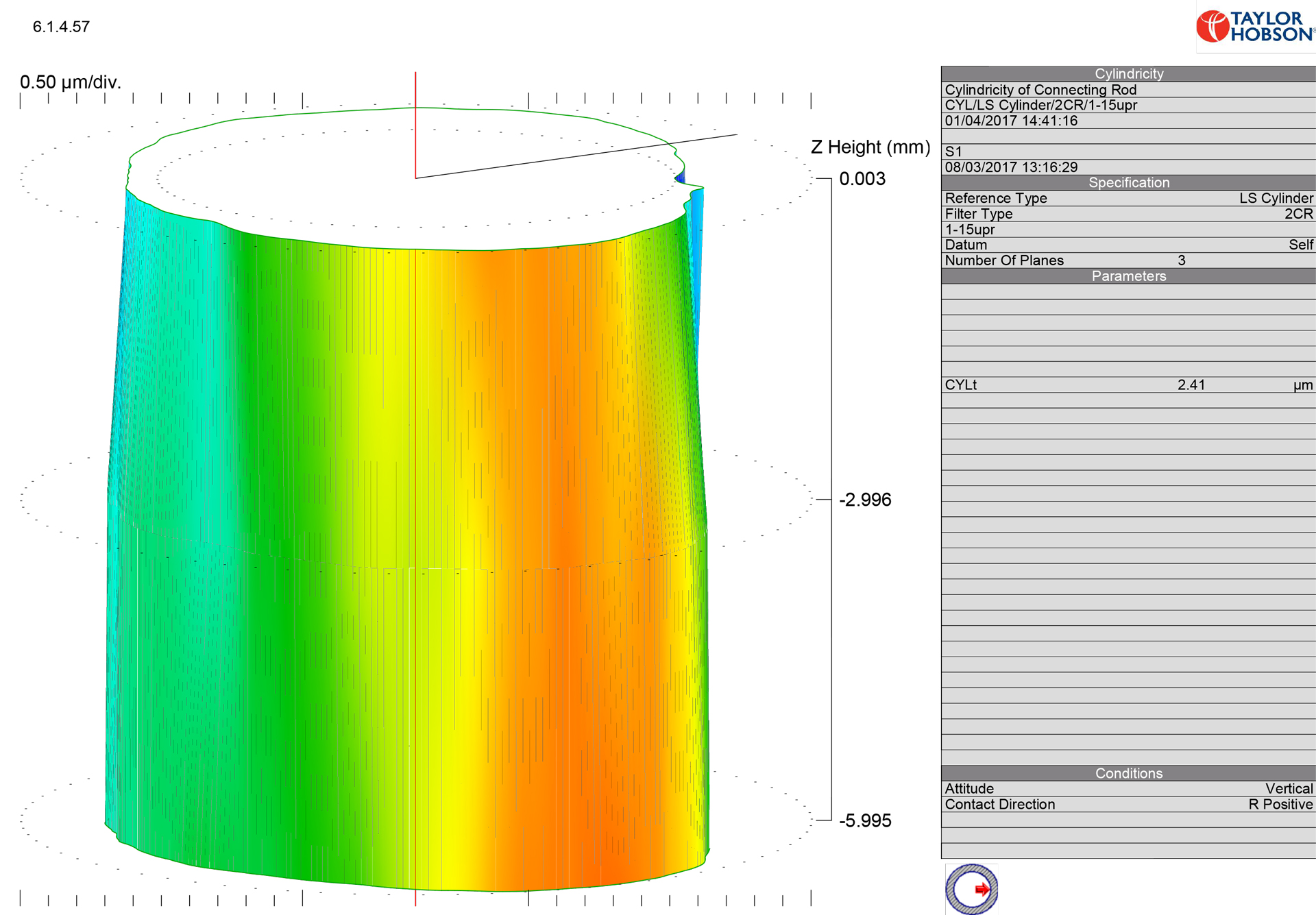

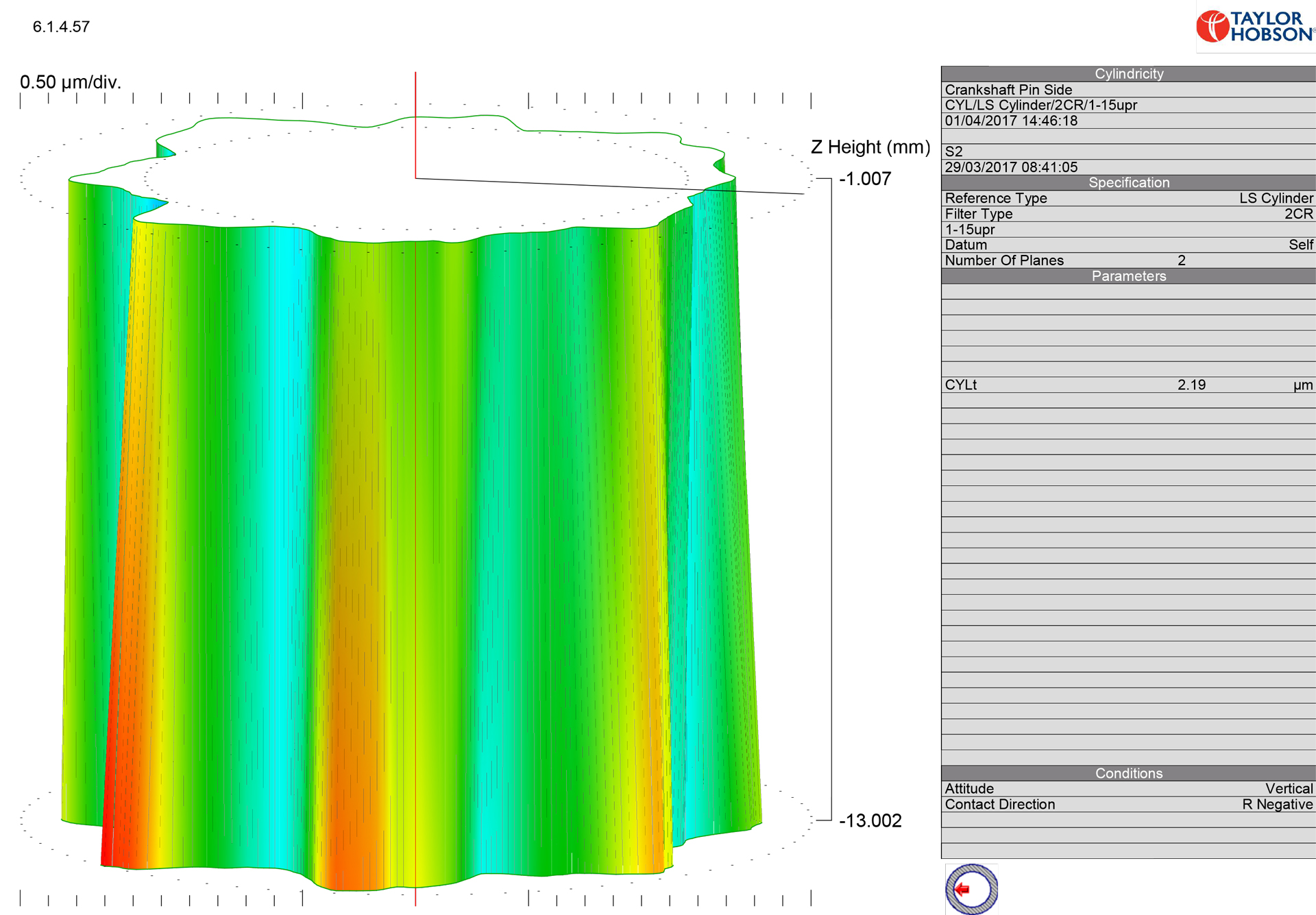

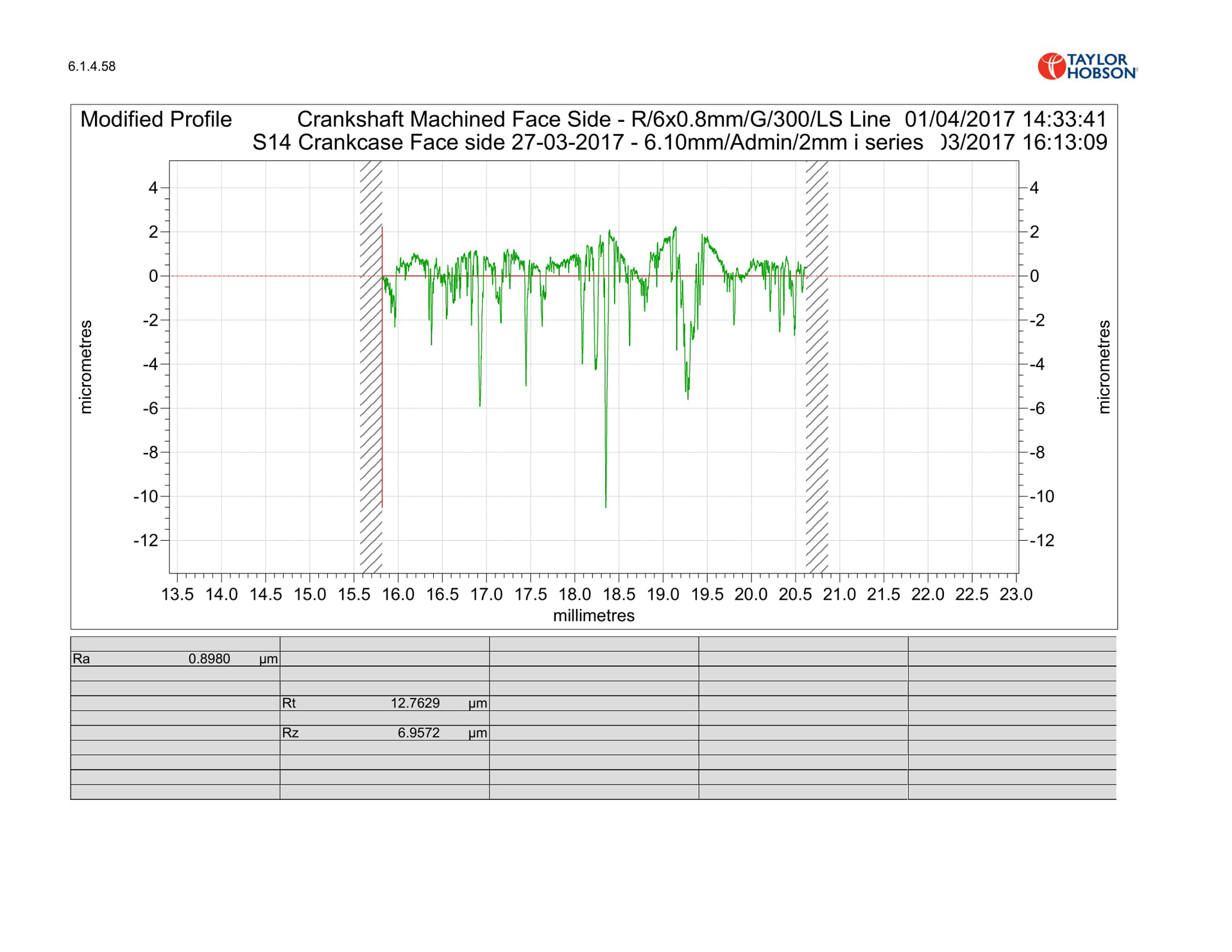

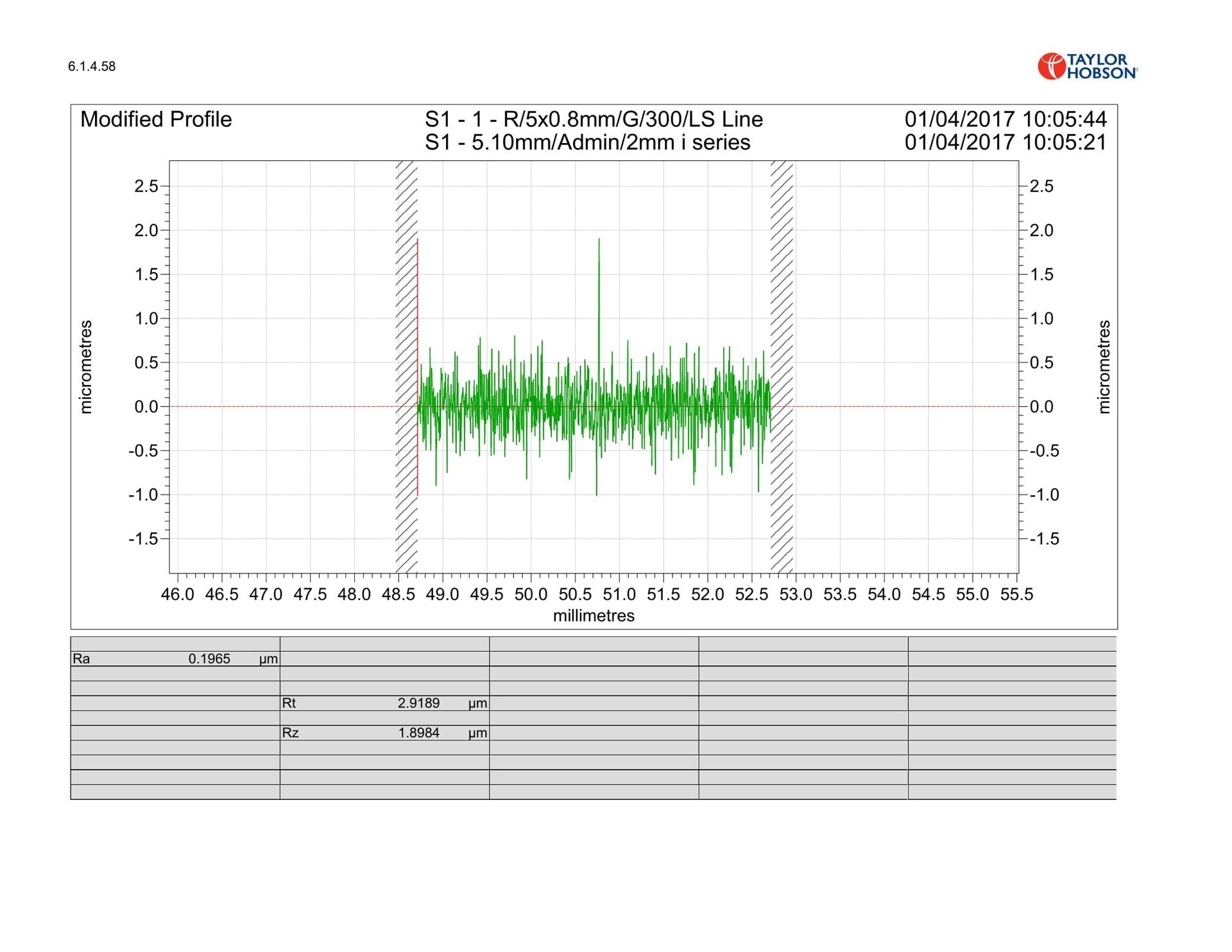

Metrology Lab:

Height gauge: Accuracy- (1.1+0.6L/600) µm.

Vision measuring system: Accuracy- (1.9+L/100) µm,1D and (2.9+L/100) µm.

CNC CMM: Accuracy- (1.8+L/300) µm.

Surface roughness and Contour machine: Accuracy- Roughness 0.25 µm and Contour 0.50 µm.

Roundness machine: Accuracy 0.25 µm.

Materials Testing and Analysis Lab:

Wire Testing Facilities

Hardness Testing Facilities

Macro and Micro Analysis facilities

Spring Testing Facilities

Gasket Thickness Measurement Machine

And also contains versatile testing machines for checking different raw materials characteristics

Overload Test Machine

Quick Test Machine

Locked Rotor Test Machine

OLP Test Machine

Noise Testing Chamber:

Testing facilities for the measurement of Noise, Vibration and Gas pulsation

Background Noise Level < 10dB

Standard : ISO 3744

Life Testing Machine:

28 benches are dedicated to perform Wear, High Temperature and ON/OFF Test

Standard: CECOMAF GT4

"We are extremely confident on best quality, so everything remains exposed."

|

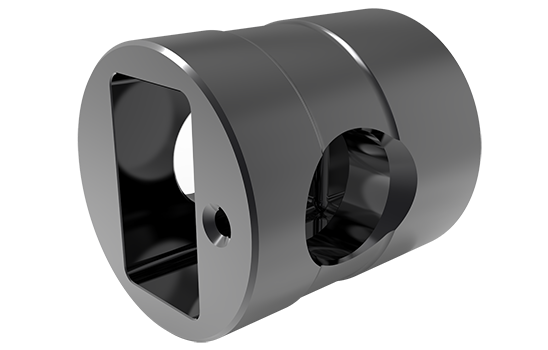

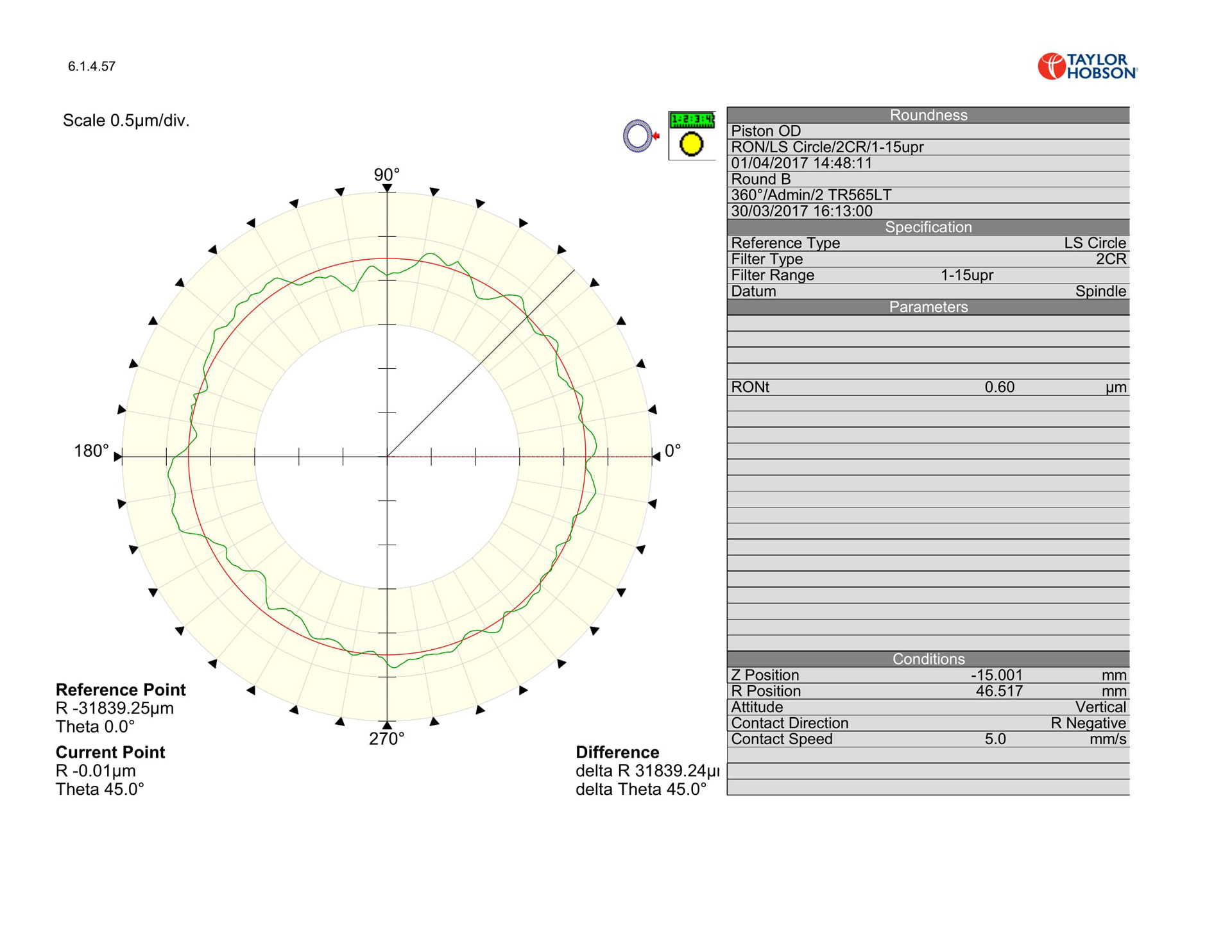

Piston

|

|

|

Piston is a crucial part of reciprocating compressor. The Piston of our Compressor is made of Sintered Iron. Its main purpose is to transfer the highly compressed superheated refrigerator into the compressor discharge line through discharge valve at high pressure. Our piston is very modern and very low frictional in design, robust in construction. Its leak proof capability is up to 25 bar.

|

|

|

Property:

|

|

|

|

|

Connecting Rod

|

|

|

In a reciprocating compressor Connecting Rod transfers rotary motion from crankshaft as a reciprocating motion to piston. The connecting rod of our compressor is made of Sintered Iron. It can withstand force up to 240 MPa. Its damping capability is also very good.

|

|

|

Property:

|

|

|

|

|

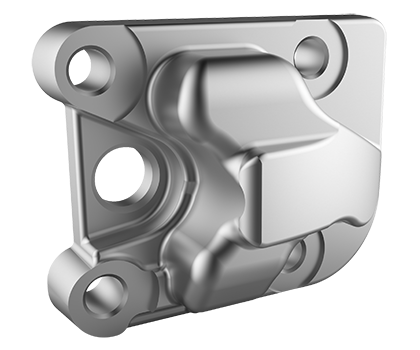

Crankcase

|

|

|

Crankcase is the heavy, rugged part that has integrated cylinder block and four inch discharge line, especially designed to dampen the pressure fluctuation of the discharged gas. It works as the base on which all the rotating parts; valve group and cylinder head are mounted. This is casted from Grey cast iron undergoing special heat treatment to improve its machining process.

|

|

|

Property:

|

|

|

|

|

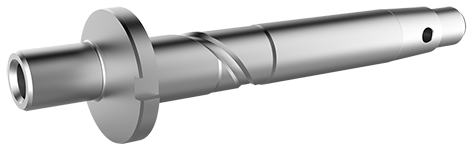

Crankshaft

|

|

|

Crankshaft performs a conversion between reciprocating motion and rotational motion. It converts the rotational motion from the Rotor into the reciprocating motion of the Piston through connecting rod. It’s a robust part casted from Grey cast iron having integrated oil pump and long main bearing.

|

|

|

Property:

|

|

|

|

|

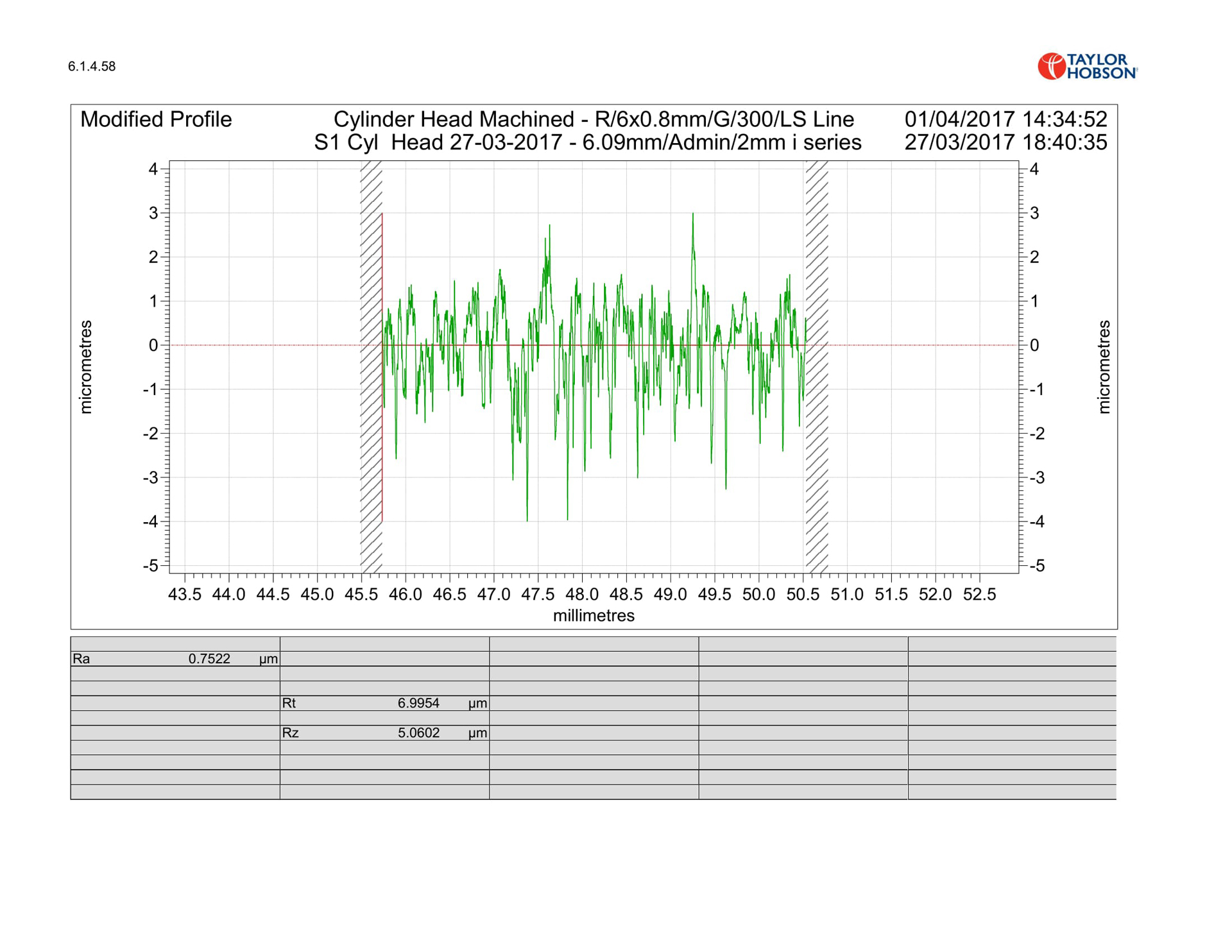

Cylinder head

|

|

|

In a hermetic compressor the cylinder head (often informally abbreviated to just head) sits above the cylinders on top of the cylinder block. It closes in the top of the cylinder, forming the pressure chamber. This joint is sealed by a head gasket. In most compressors, the head also provides space for the passages that feed gas to the cylinder, and that allow the pressurized gas to escape.

It forms the pressure chamber that creates spaces for passages of the feed gas to the cylinder, and that allow the pressurized gas to escape. |

|

|

Property:

|

|

|

|

|

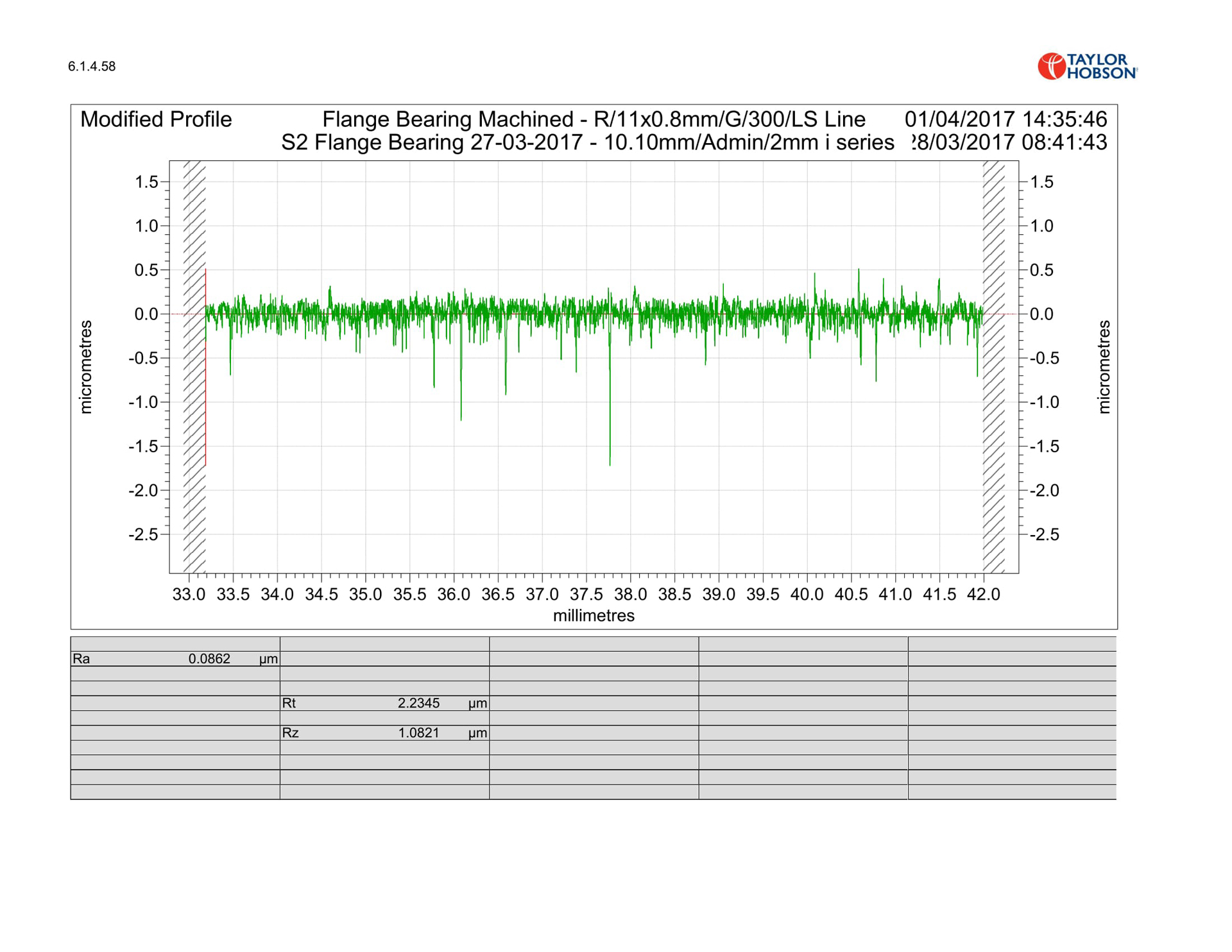

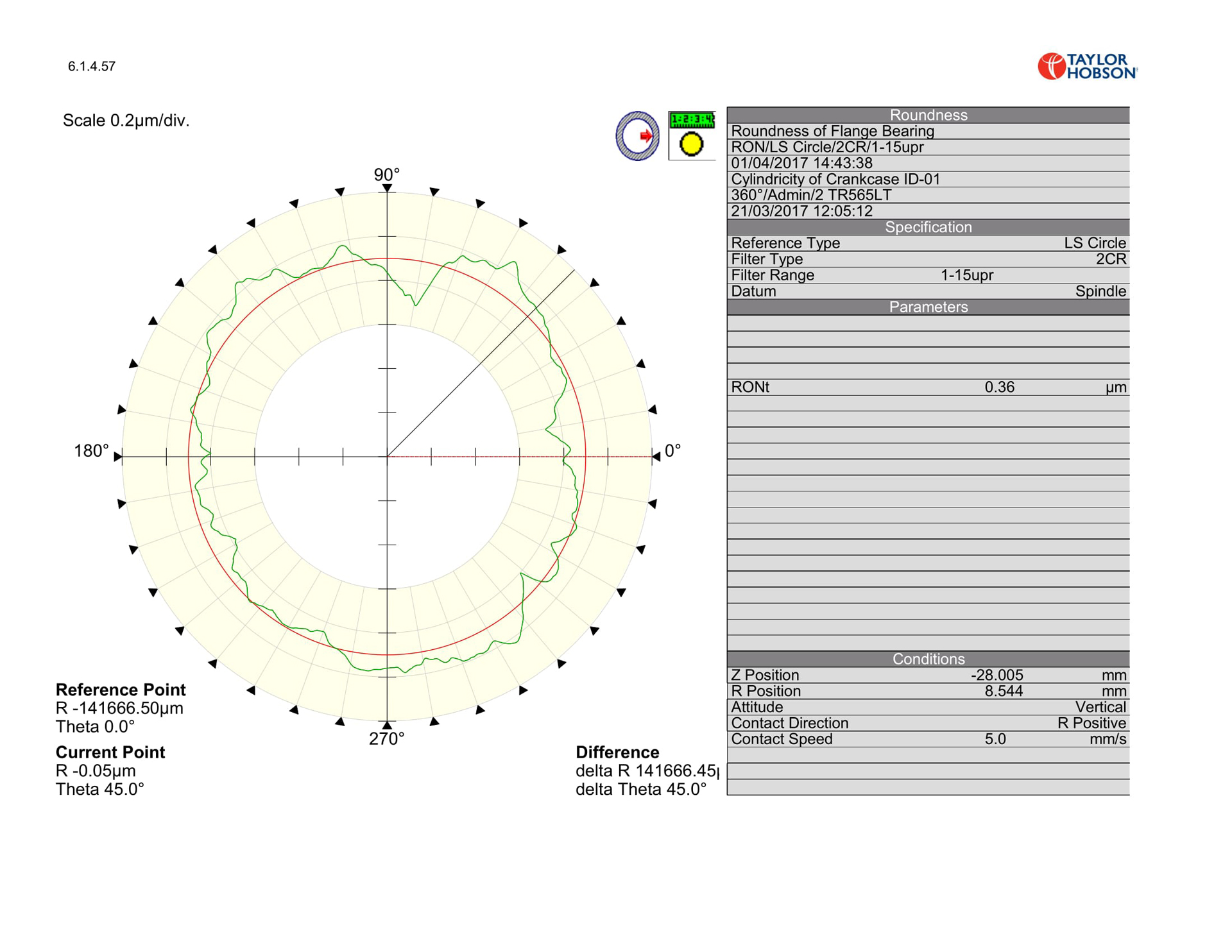

Flange Bearing

|

|

|

Bearings with a flange on the outer ring are known as flange bearing. The housing for such bearings consist of a through-hole of uniform diameter, but the entry face of the housing (which may be either the outer or inner face) must be machined truly normal to the hole axis. However such flanges are very expensive to manufacture.

|

|

|

Property:

|

|

|

|

|

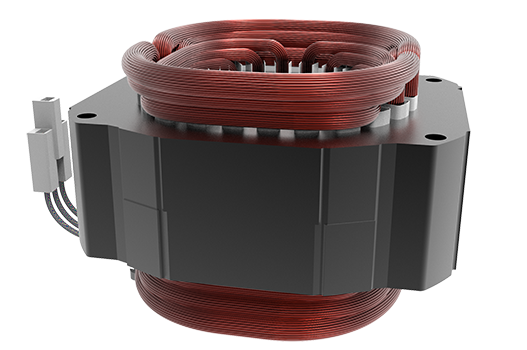

Stator

|

|

|

Stator is the main power house of the compressor. It creates magnetic field that induces on rotor and then in fundamental rule of electromagnetic induction-torque generation; the rotor gets the driving torque to rotate. Our Stator has 24 slots with high graded enamel coated copper wire. Its insulation can sustain up to 200 degree Celsius temperature which is far enough to sustain a harsh condition. The laminations used in the stator are the highest graded silicon steel around the world. Its slot fill factor is almost 0.91 with an overall efficiency of 86%. Together it is one of the most iconic low power consumption designs of the world.

|

|

|

Property:

|

|

|

|

|

Rotor

|

|

|

A rotor is the central part of an electric motor. Our rotor is engineered to get maximum possible starting torque and efficiency. To get maximum combined efficiency, we use highest graded aluminum with a purity of 99.7% to cast our rotor. We use world famous THT (USA) and Bühlar (Switzerland) machines to cast our rotor, which gives us micron level precision in the final product. We select 28 slots in rotor stack, together with stator that give almost zero vibration in rotor rotation. For this our compressor has very low vibration and therefore the noise.

|

|

|

Property:

|

|

|

|

|

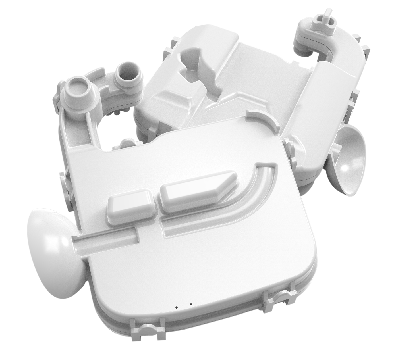

Suction muffler

|

|

|

Its main function is to separate oil from the circulating gas. In addition its design is so matched that, it absorbs noise that creates inside of the compressor.

|

|

|

Property:

|

|

|

|

|

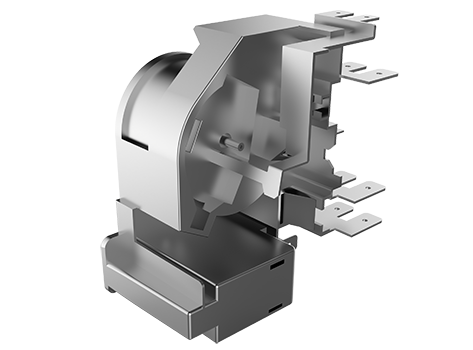

Terminal board assembly

|

|

|

This item is actually a combination of overload protector (OLP) and positive temperature co-efficient relay (PTC). OLP protects the compressor from overload situation from reverse rotation; and PTC works as a starting device, for this our compressor is completely safe in highly load shedding zone.

|

|

|

Property:

|

|

|

|

|

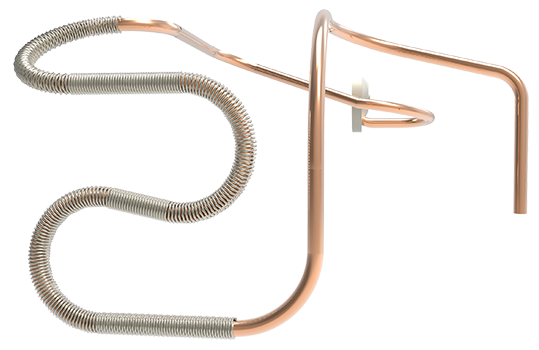

Internal Discharge Tube

|

|

|

Its main function is to reduce noise, vibration and control the flow of gas.

|

|

|

Property:

|

|

|

|

|

Valveplate

|

|

|

Valve plates provide operators with a comprehensive range of both metallic and non-metallic plate valve assemblies and internal components, manufactured to the highest quality. Achieving the optimum performance and reliability which are keys to most operators to deliver valve plates across the broad spectrum of applications and operating conditions required. Our valve plates are machined with highest grade steel.

|

|

|

Property:

|

|

|

|

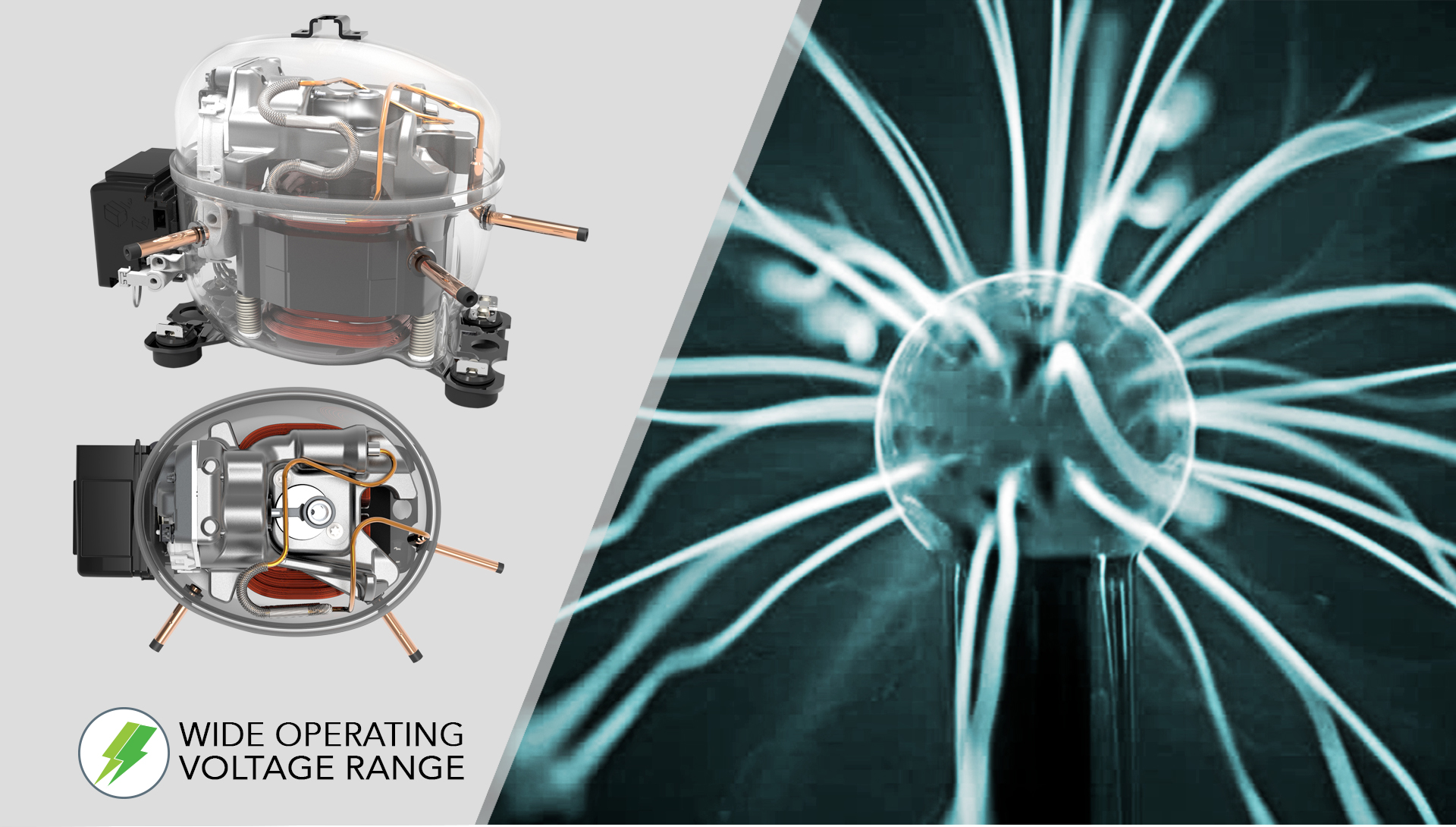

To minimize the effect of voltage fluctuation, expert R&D engineering team continuously works on the development of starting technology for the Compressor functioning at both low and high operating voltages. As a result, we are able to offer a spectrum of products that come with wide ranges of operating voltage, which can meet your demands accordingly.

Energy efficiency is the prime concern while developing all kinds of products in Walton. Skilled R&D engineers are continuously researching on the development of Compressor to make it more efficient, quieter and more ecological. Thus, by our relentless dedication we are offering a full product range that offers compressors of standard efficiency.

Walton innovates to build a more advanced, sustainable and environment friendly society through the combination of sophisticated technologies and expertise. Walton does not compromise with the quality issues of the products. We’ve built in-house advanced laboratory facilities from the best testing equipment manufacturers all over the world to ensure high quality products, strictly following the International Standards.

Features and Benefits:

- Optimum efficiency